Copper is an important component in many modern technologies and is used in capacitors for everything from computers to mobile phones to electrical appliances. Despite its importance in the world today, copper mining takes place in very few countries. HOMA Group's presence has been felt by the unconditional commitments we have covered and hence bringing our customers new business opportunities.

Copper cathodes are primary raw material which is used to manufacture the copper tubes, copper wire, cables and etc. It's a primary raw material which is used to manufacture pure copper which is converted into several other products like cables, tubes, sheets which are used by most of the industries to make appliances, machineries and other products.

The element Copper is found in a variety of minerals in the earth's crust. Its uses are many. On the periodic chart of elements it is identified by the symbol "Cu". The first step in processing the ore removed from the mine is to break the large rocks of ore into smaller pieces. This is accomplished by a variety of subsequent processing steps. The next step in the process flow is smelting for sulfide ore concentrate and solvent extraction for oxide ore leach solution. Copper cathode from the smelter is melted and cast as anodes, the solution from the solvent extraction process moves to a plating operation. The final step in processing sulfide ore copper from the smelter is to make high purity copper cathodes. HOMA Group as being experienced copper cathode supplier has the factories agency which has the rights of selling copper cathode to the manufacturers and end users.

Over the past 20 years, global copper consumption has been doubled and, according to global forecasts, demand for metal will continue to grow. The production of copper cathode products takes place in four stages: ore mining, ore enrichment and production of copper concentrate, processing of copper concentrate and obtaining refined copper cathode. HOMA Group is active in extraction of copper ore in open and underground mines with their associates to have direct control on copper production in different regions in the Middle East.

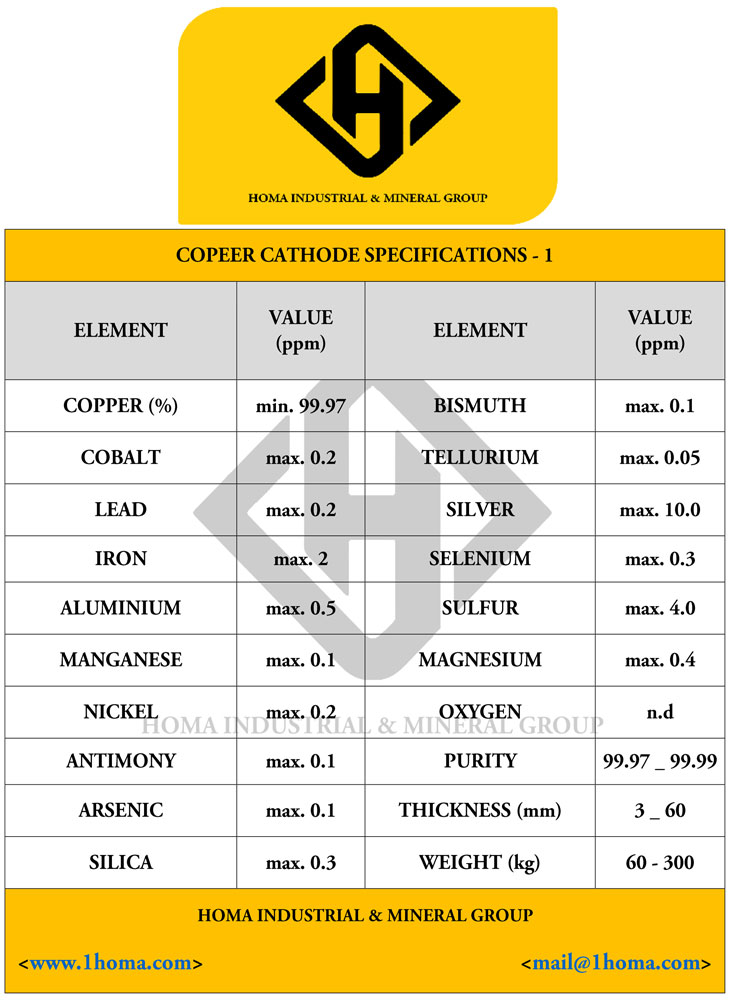

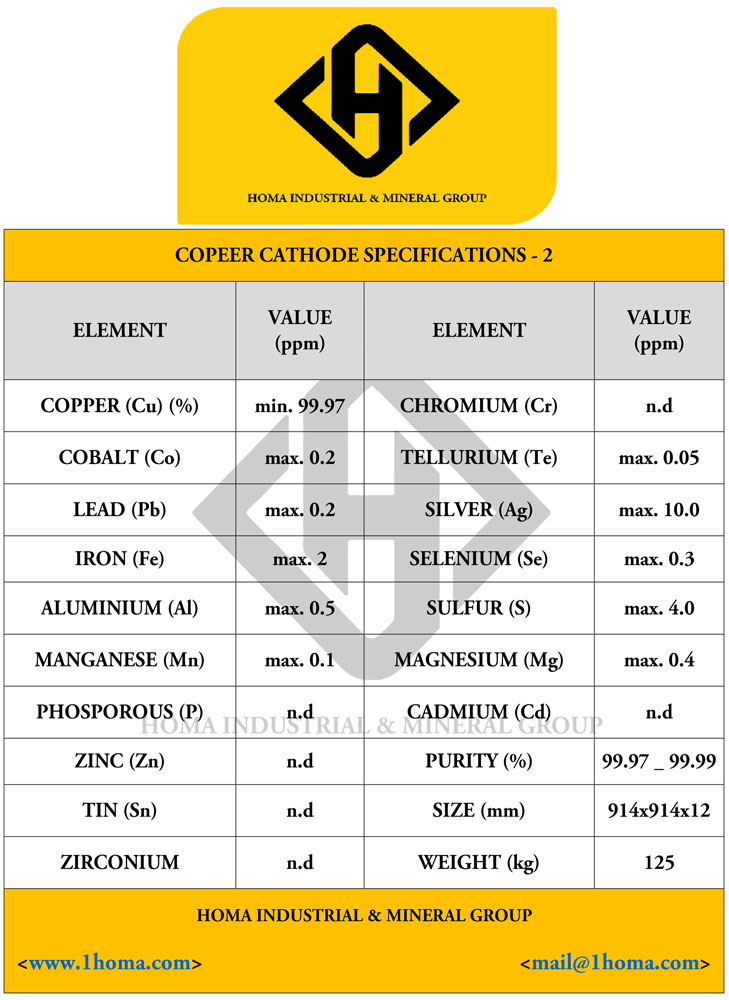

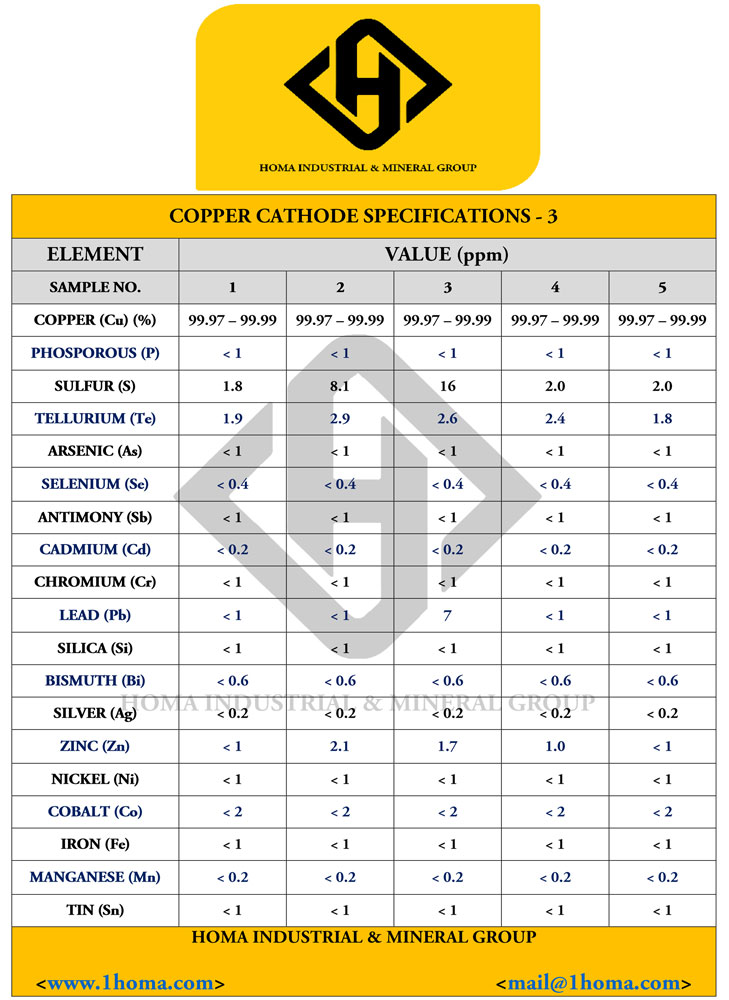

HOMA Group's copper cathodes are known for their high purity and consistent quality, which are square-shaped plates of different thickness, with 99.97 to 99.99 % copper purity levels which are produced using the Mount ISA electro-refining process.

Our copper cathodes meet International Quality Standards such as BS 6017 1981 (1989) and u-Cath-1 / ASTM B-115 (1999) and are registered as A-Grade cathode on London Metal Exchange (LME). HOMA Group's Copper cathodes are high-grade, and have the lowest levels of impurities.

We supply Copper cathodes which are used in manufacturing of continuous cast copper rods which are further used for the wire, cable and transformer industries. They are also used for the manufacturing of copper tubes for consumer durable goods and other applications in the form of alloys and sheets.

The goal of HOMA Group is to become one of the most successful and high-tech copper cathode suppliers in our core region. HOMA Group relies on the efficient development of copper deposits in the Middle East. Our group uses the best-refined copper cathode manufacturer solutions available in terms of technology and environmental safety.

You can find some of our Copper Cathode specifications as below:

Kindly note that we're able to supply other Copper Cathode specifications regarding to customer's demands.